7 Tips for Extending the Lifespan of Your Laser Cleaning Machine

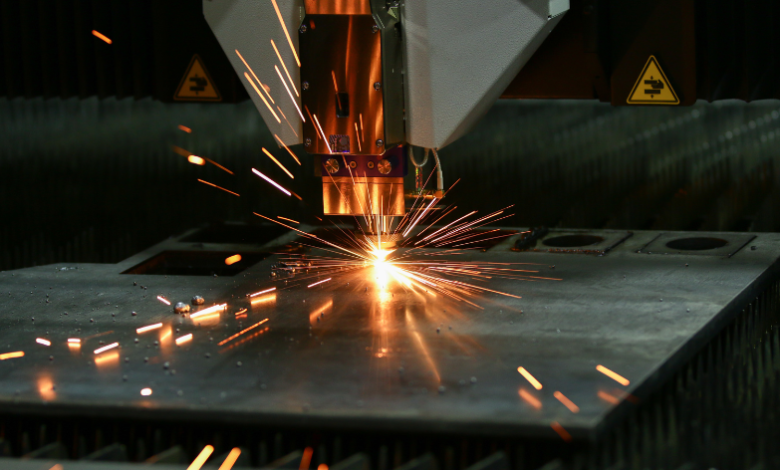

Laser cleaning machines hold a vital position in industrial cleaning. These machines are powerful tools that remove impurities from surfaces. Laser cleaners take a unique approach in a field filled with dirt and grime. They use intense light beams to remove contaminants from materials with precision. The cleaning process is also non-contact and does not damage the material.

Furthermore, it is also eco-friendly. This process eliminates the need for harmful chemicals and practices. This makes laser cleaning machines the perfect cleaning solutions for environment-conscious companies.

But even for these valiant tools, proper care reduces performance and efficiency. Maintenance is the key to getting the best results from your laser cleaner. This comprehensive guide is here to fulfill your current needs. Here, you will find valuable tips for extending the lifespan of your laser cleaning machine. These pointers guarantee that your device remains in perfect working condition for years. Read on to learn more.

Tips for Extending the Lifespan of your Laser Cleaning Machine

-

Cleaning the Optical Components:

The heart of your laser cleaner lies in its optical components, which are the lenses, mirrors, and the laser head itself. Ensure you always inspect these parts for dust, debris, or contamination. To make the inspection easier, consult your user manual for the proper cleaning steps. Use only the cleaning solutions specified in the manual. Harsh chemicals or rough clothes are a definite no for these delicate components.

1.Filter Focus:

By nature, laser cleaning machines release fumes and particles that clog up their filter systems. A clogged filter is bound to reduce efficiency and strain the machine. Thus, you should make a regular filter cleaning or replacement schedule for your machine. This schedule should complement your usage patterns and follow the manufacturer’s recommendations.

-

Invest in Operator Training:

Train your operators on how to use and maintain laser cleaning machines. The training should cover everything from;

- safety rules and regulations,

- cleaning techniques,

- parameter adjustments, and

- basic troubleshooting issues.

An operator is an extension of your machine’s intelligence. Training your handlers not only keeps them safe but also increases your device’s lifespan. In addition, encourage your workers to practice preventive maintenance. They should be observant and report any unusual developments during the cleaning process. It will help identify minor issues in time and prevent them from escalating.

-

Environmental Control:

- Heat:

Laser cleaners operate within specific temperature ranges, which you may refer to as their “comfort zones.” Excessive heat affects their performance and also shortens their life expectancy. So, make sure there is proper ventilation around the machine. If necessary, use an AC system to maintain a cool working environment.

- Humidity:

Aside from heat, humidity is another enemy of your laser cleaning machine. If your humidity levels are high, condensation occurs within the machine. Following condensation are instances of corrosion and electrical issues. Dehumidifiers are handy tools to have in humid environments. They keep your working space dry and allow your laser cleaner to thrive.

- Dust:

You may find dust bunnies cute, but dust is a severe issue for laser cleaning machines. A dusty environment increases the chances of clogged filters and contaminated optics. To avoid these nuisances, clean your workplace frequently to prevent dust build-up.

-

Consumable Care

Some parts of a laser cleaner are called consumables. These consumables experience constant wear and tear and need frequent replacement. The nozzles and protective windows are examples of consumables. When replacing these parts, it is best to follow the directions in the instruction manual. This process may be a preventive measure to maintain peak cleaning power.

-

Maintain Electrical Systems:

Laser cleaning machines are sensitive to electrical fluctuations. Therefore, you must protect your machine from power surges and spikes that could damage its components. To avoid this issue, invest in a high-quality surge protector. It will help you maintain a clean and consistent power supply to your machine. It will, in turn, guarantee reliable operation and an extended lifespan. Another way to ensure a constant power supply is to check your cables and connections. Inspect your cables for wear, tear, or loose connections, then replace or fix them if necessary.

-

Safety First, Always:

It would help if you prioritized your safety when using laser cleaning machines. Laser cleaners are powerful tools, so you must follow specific safety guidelines. Also, ensure your operators learn about these safety protocols, practice what they know, and use the appropriate protective gear while working.

Conclusion

The practices outlined in this post will help you transform your laser cleaning experience. Your laser cleaner will deliver peak yearly performance by following these maintenance tips. We at HANTENCNC hope that you integrate these practices into your cleaning process. Our tips guarantee that your device works with precision and efficiency.